From design challenge

to original solution

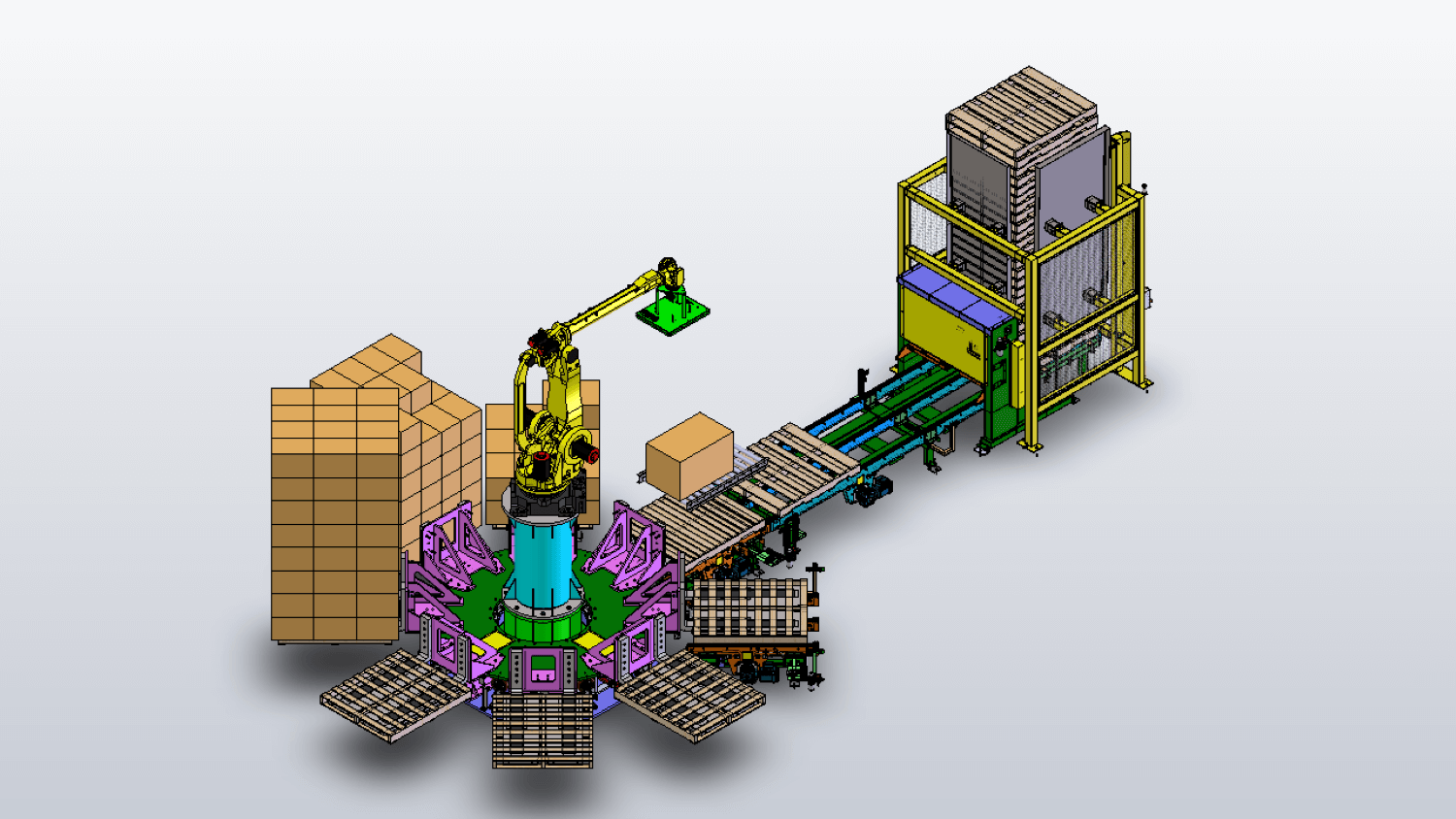

Our application and engineering staff look “outside the box” to develop your automation or material handling project. Applications experts assess your project and recommend a solution, including a sequence of operation and custom layout.

Engineering works with you during the project to make sure our solution is customized to fit your exact needs. From the preliminary budget phase through the commissioning of the project, our team works for you.

In the distribution and robotic integrator arena, many companies are specialists, offering a few targeted solutions. We’re the opposite. We are generalists. We’ve designed hundreds of solutions, all exceptional and engineered to last.

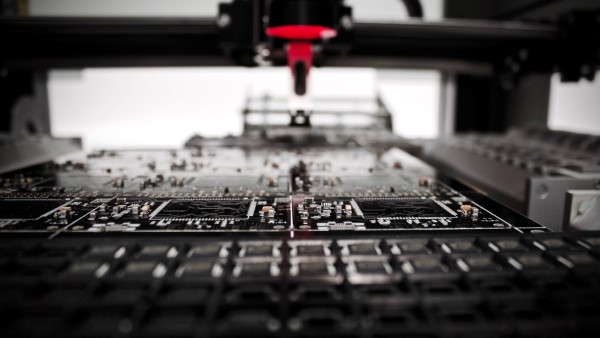

A culture of design:

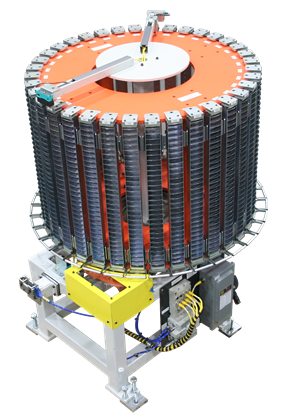

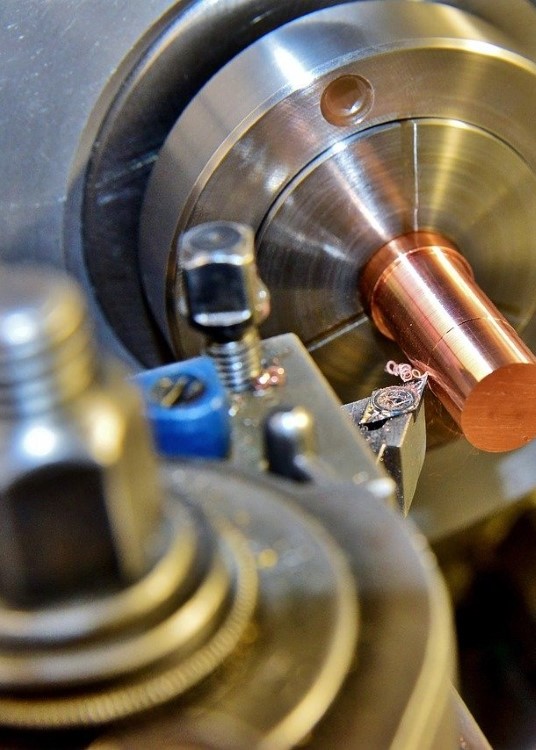

- Minimize equipment and machining complexity

- Minimize stock and fastener sizes

- Utilize pre-engineered commercial components

- Manufacturing drawings come from parametric 3-D models

- Electronics and pneumatics included in mechanical designs

- All first-time inquiries look like 4th or 5th generation products

- Machine guarding, wiring and plumbing 5/5 stars

Get started today:

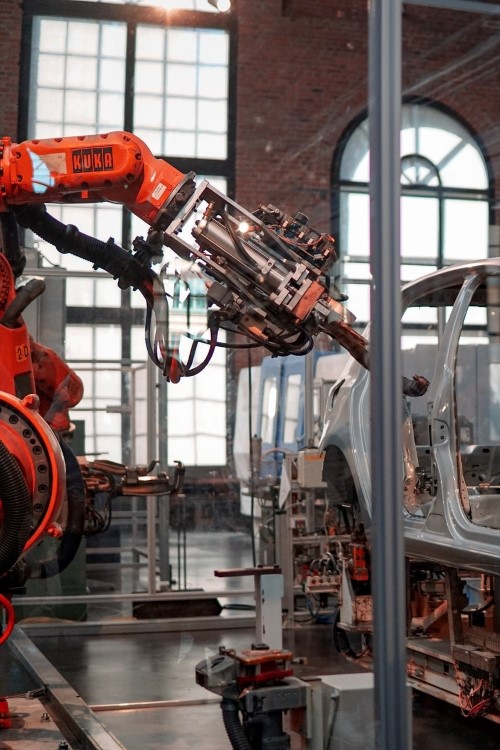

Supporting Robot Integrators

We also support robot integrators and love serving up creatively engineered designs. If you are a robot integrator, we are uniquely able to meet your specification requirements, for any manufacturing system application.

We have designed packaging and material handling systems for Amazon, Caterpillar, FedEx, and GM, as well as smaller firms needing specialized equipment. Look to us as your provider for the finest in material handling equipment and automation technologies.